Quality Control

We strictly adhere to HACCP principles in both production and employee management. Our staff are proficient in all processes, ensuring that every customer benefits from Kimdee’s quality management.

- Home

- Quality Control

Rigorous

Quality Management

We uphold stringent quality control standards to ensure each process, from raw material procurement to final product shipment, meets the highest standards.

Raw Materials Procurement

- Professional QC Team: Our dedicated team inspects all organic ingredients upon delivery.

- Mandatory Documentation: Suppliers must provide a business license, factory report, and inspection report. Only materials that pass our verification are accepted into inventory.

- Re-testing for Certain Materials: Some raw materials undergo additional testing to ensure they meet our high standards before being used in production.

Production Process Control

During the production process, our quality control team rigorously samples each stage according to standards, ensuring adherence throughout production.

Sampling Frequency During Our Production

- Sieve Mesh and Foreign Object Inspection: Operators conduct checks for every batch of flour, with on-site quality control inspections every 60 minutes.

- Palm Oil Acid Value and Peroxide Value for Fried Noodles: Testing conducted every 2 hours during production.

- Air Drying Temperature and Duration: Operators inspect every 30 minutes, with on-site quality control checks every 60 minutes.

- Moisture Content of Noodles: Testing performed every 4 hours.

- Metal Detector/X-ray Machine Standard Testing: Packaging workers conduct checks every 30 minutes, with on-site quality control inspections every 60 minutes.

Finished Product Inspection

We conduct laboratory testing on each noodle cake to ensure compliance with standards. We randomly sample and retain products for one year to uphold our commitment to traceability.

Appearance:

- Color

- Taste and Odor

- Shape

- Rehydration

- Impurities

Ingredient content indicators:

- Moisture Content

- Acidity Value

- Peroxide Value

- Microbial Count

We ensure that the net weight deviation of all noodles does not exceed -3%.

Depending on the process, we also strictly control the moisture content, acidity value, peroxide value, and microbial count for both fried and non-fried noodles, all within standard ranges.

Inventory Storage

We prioritize both product quality and logistics services. Our modernized warehousing is your advantage. All qualified products are neatly stored and ready for shipment. Our professional warehousing and transportation team ensures smooth delivery to your warehouse.

Professional Laboratory

Quality testing is conducted in our advanced laboratory. All operators are HACCP-trained, demonstrating excellent awareness and expertise.

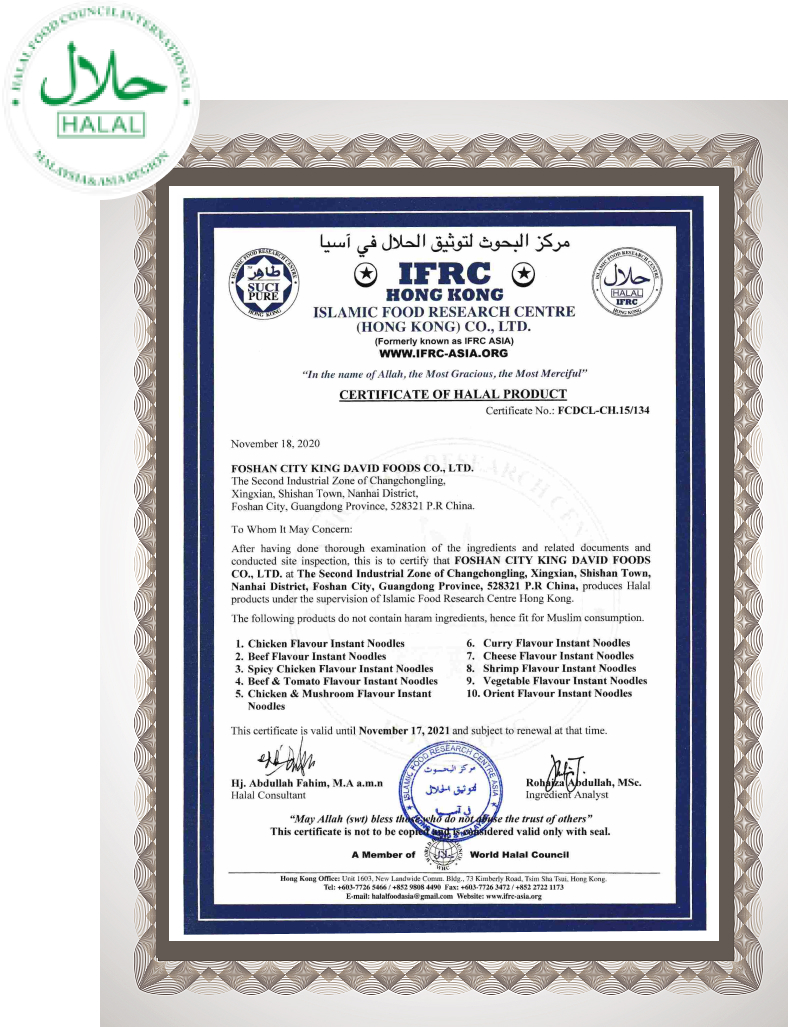

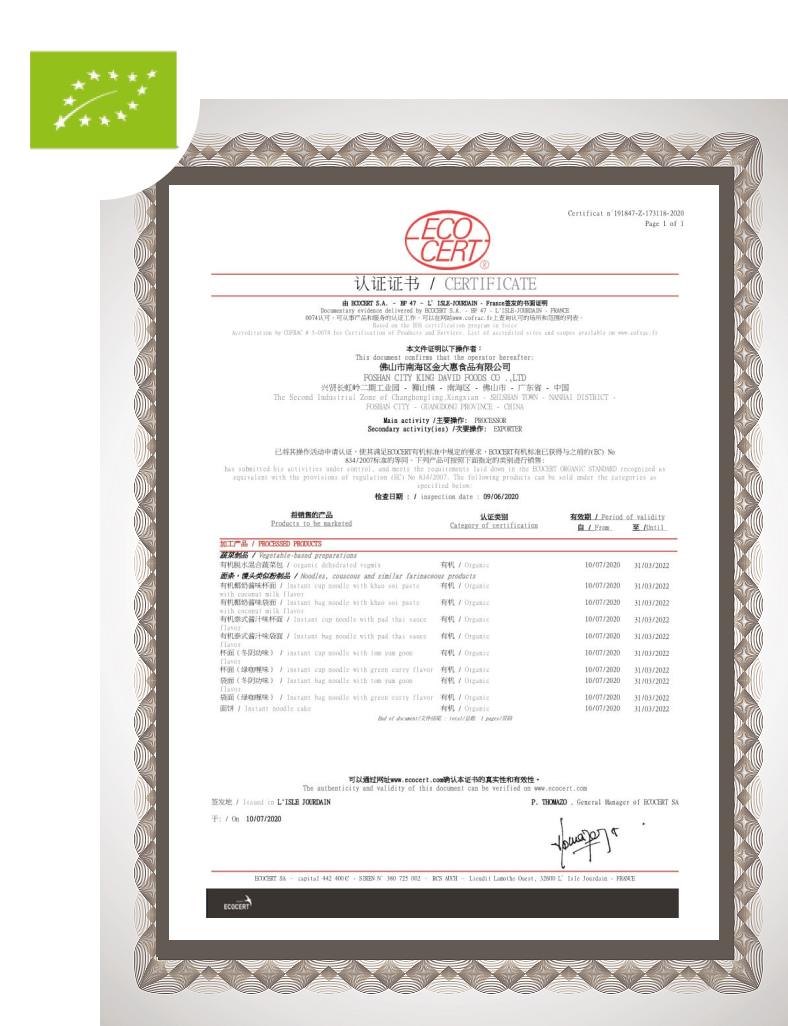

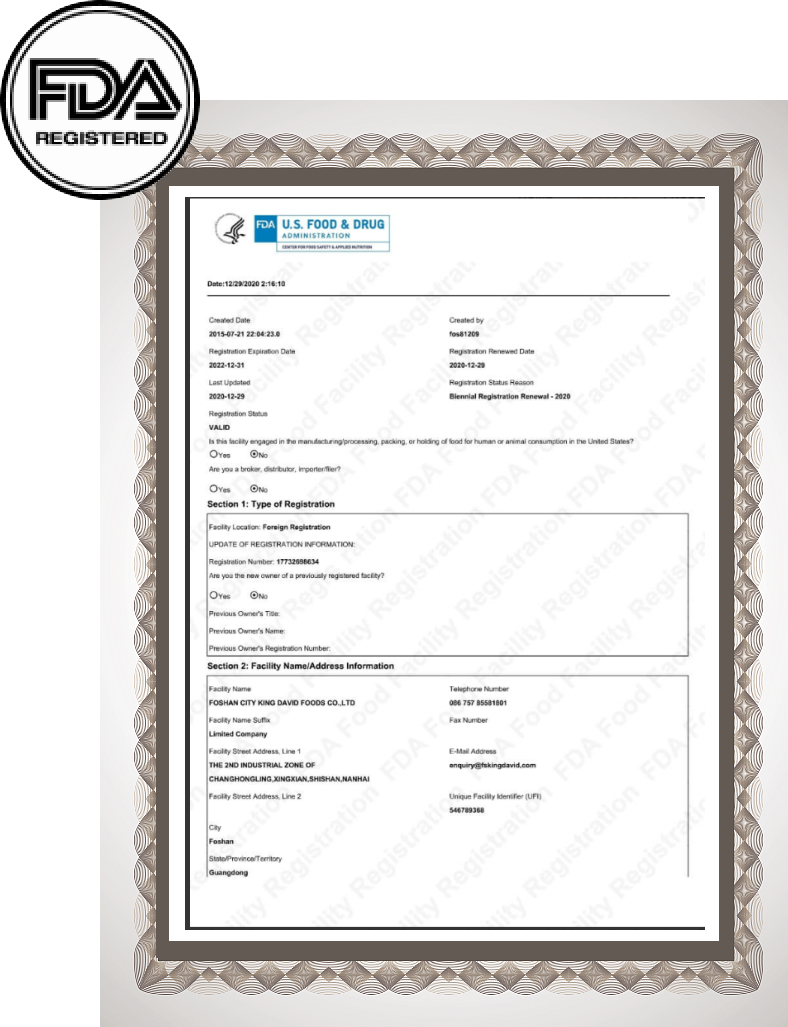

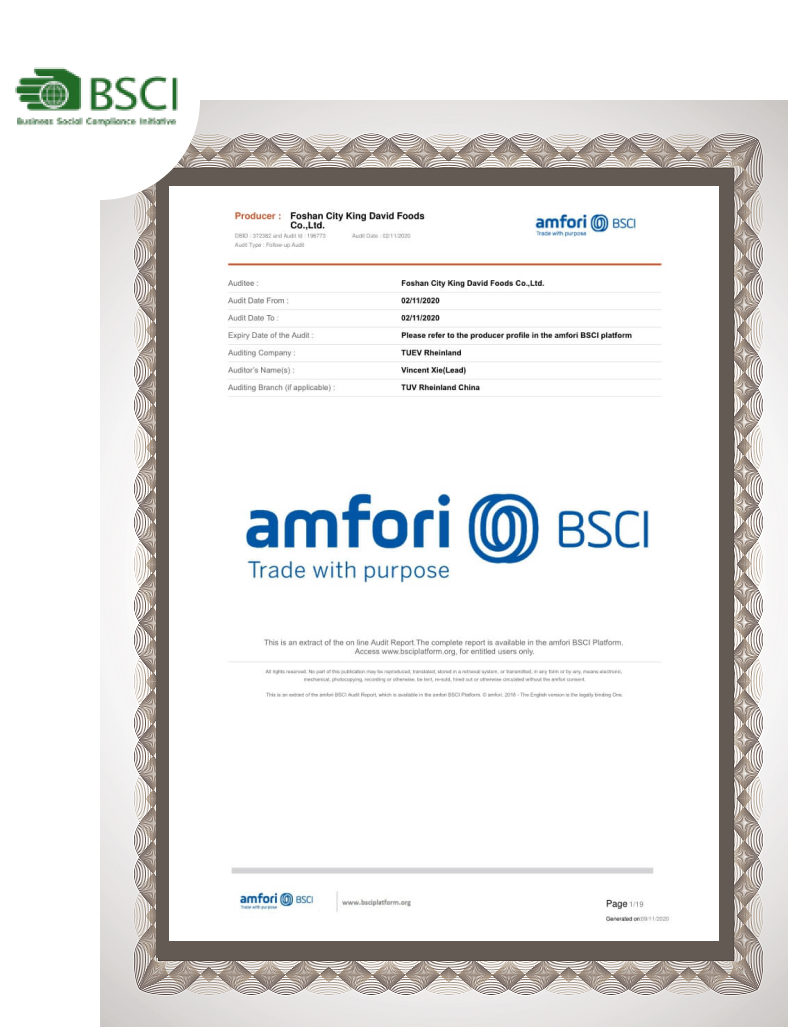

Trust Kimdee: Certified Quality Assurance

Kimdee holds multiple international certificates, all inspected and validated by authoritative bodies. We ensure high-level food safety.